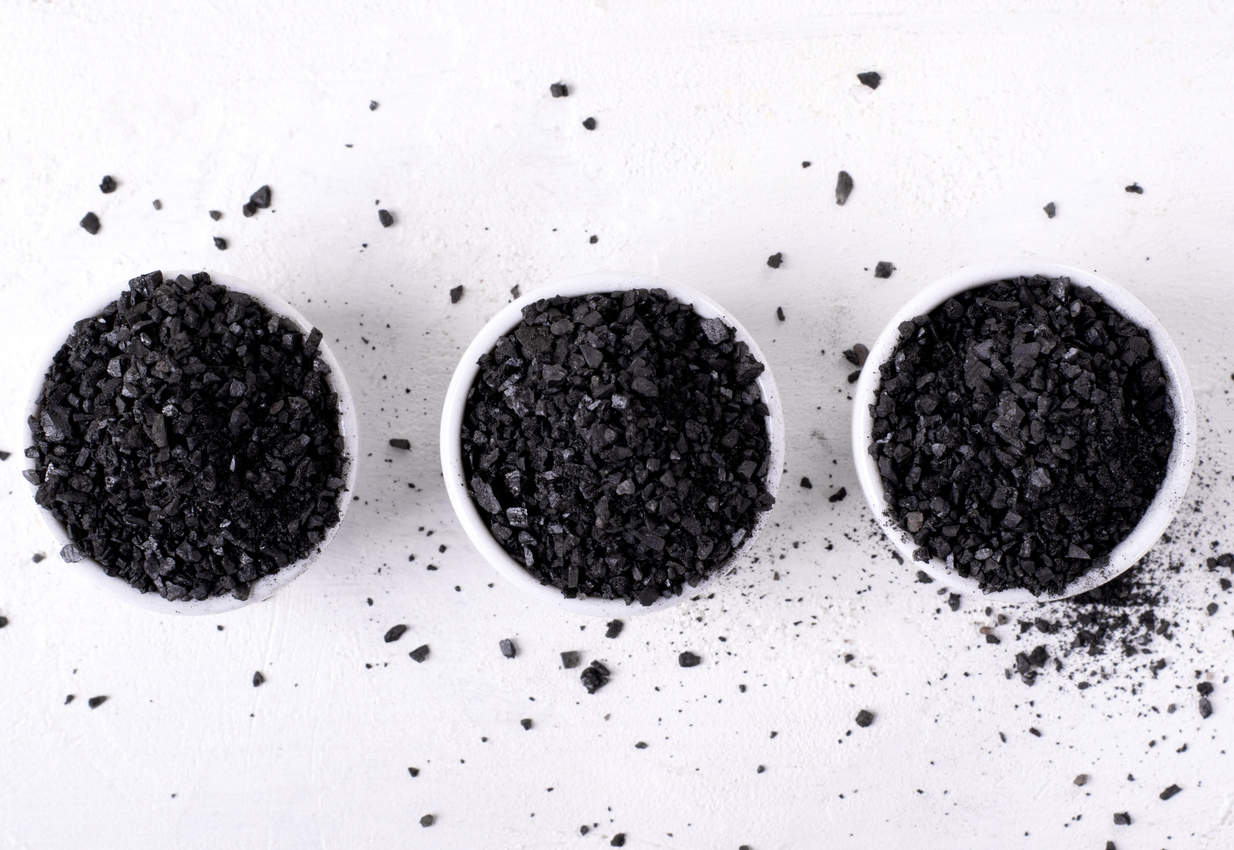

Granular activated carbon consists of organic material with a high carbon content. Exposure to heat without oxygen causes the surface of the carbon to become “activated.” Once the granular activated carbon is activated, it can be very effective at attracting and binding to its surface various chemicals and contaminants.

Such qualities allow activated carbon to serve as an effective water filtration medium. Technically, activated carbon comes in several forms. As the name suggests, in granule form, activated carbon appears ground up, with a texture almost like rough sand.

Granular activated carbon can degrade over time. Understanding the basics of the process can help you strategize how you might use this filtration medium.

Benefits of Granular Activated Carbon: Recycling

There are several reasons various companies and organizations use granular activated carbon for filtration and related purposes. One such reason is the fact that granular activated carbon is often recyclable.

Over time, granular activated carbon will no longer be as effective as it originally was. One form of degradation occurs when the surface of granular activated carbon becomes too covered in contaminants and chemicals to attract any more.

Reheating the granular activated carbon in an industrial setting using specialized processes can restore it to its original (or at least close to its original) state. However, this process can be somewhat costly. Anyone using granular activated carbon as a filtration medium may want to closely monitor its filtration capacity to ensure they take full advantage of it before initiating the recycling process.

A Positive Form of Degradation for Granular Activated Carbon

When something becomes degraded, it’s usually not a positive development. However, when discussing granular activated carbon, there are instances when degradation is actually a desirable process.

Consider the findings of researchers who studied whether melamine degradation can regenerate granular activated carbon without requiring it to undergo a costly reactivation process involving the application of heat at a specialized facility.

Melamine is a chemical with many potential applications. Unfortunately, this means it isn’t uncommon to detect levels of melamine in surface water for drinking water.

Granular activated carbon can help to filter melamine out of water before it’s consumed. However, researchers have also found that using a biomass to trigger a melamine degradation process can actually help to restore a minimum of 28 percent of a granular activated carbon’s initial adsorption potential.

This process is more cost-effective than the traditional recycling process. As such, melamine degradation may become a more common method for maximizing the adsorption capacity of granular activated carbon in the future.

How to Optimize the Effectiveness of Granular Activated Carbon

There are many ways to ensure granular activated carbon is an effective filtration medium. They include:

- Studying your options: Again, activated carbon comes in a variety of forms. Discuss your goals with a supplier to choose the one that’s best for your needs.

- Testing water: Regularly test your water. Doing so will tell you whether your granular activated carbon is serving its purpose.

- Prepare for recycling: Whether you rely on melamine degradation or a more traditional recycling method, you should be prepared to recycle your carbon as soon as it stops delivering the results you aim for.

Because this filtration medium is so common, odds are many in your industry already use it. Thus, you can study their uses to determine how you may leverage activated carbon to its full potential.

Puragen offers activated carbon in granule, pellet, and powder form.